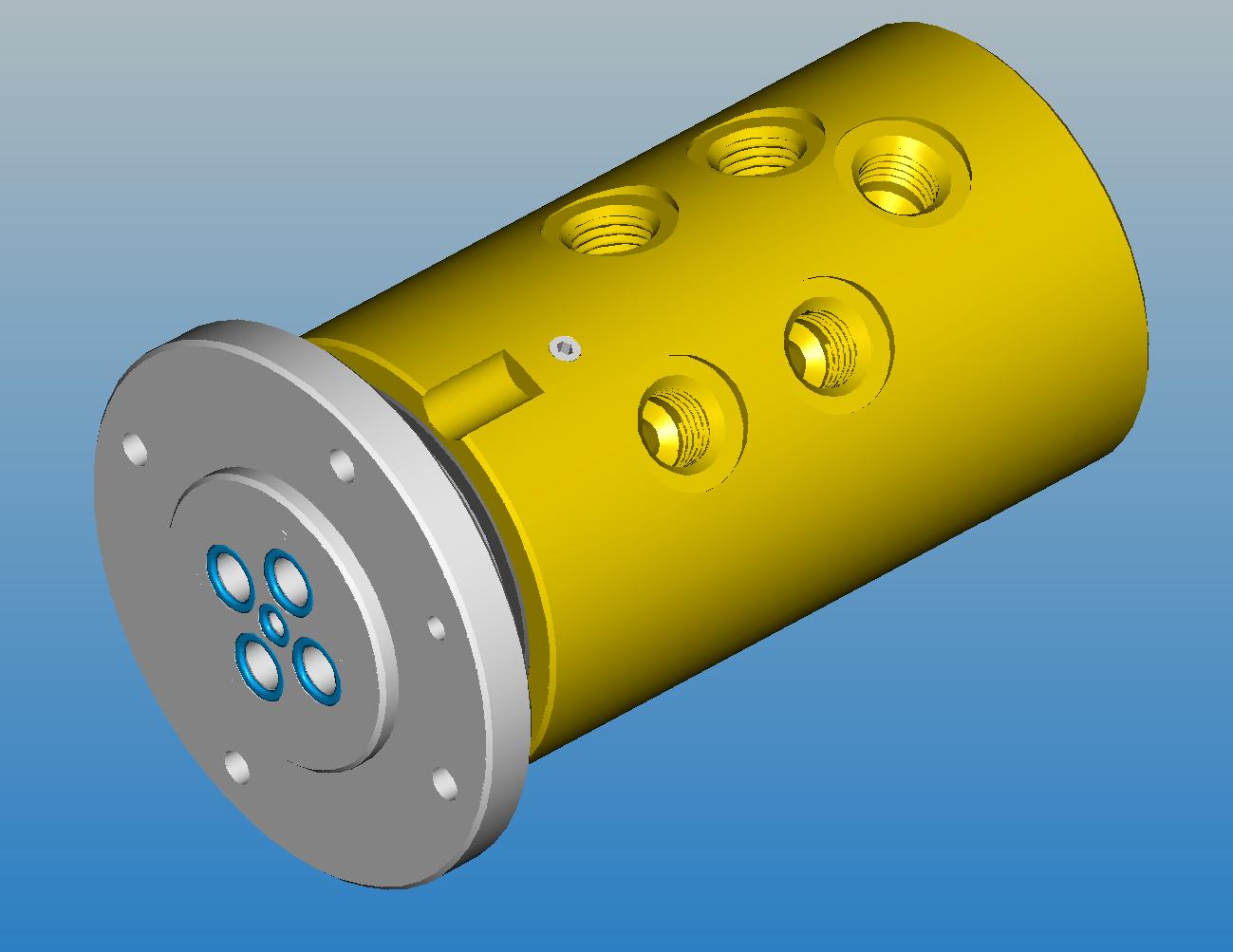

ROTARY JOINTS FOR HYDRAULIC OIL AND AIR

|

These rotating joints are used for control rotating pneumatic or hydraulic cylinders, for index tables and for watercooling of rotating circuits. Rotating joints for air and oil have housing in aluminium and rotor in hardened carbon steel, for water have housing in brass and rotor in stainless steel (hard chromed on request). Two ball bearings give the alignement. A drain port with internal connection hole preserve ball bearings from leakage when seals are worn. It is better to use the same fluid; if necessary to use two different fluids it’s possible to use other models with separate drain ports. | ||||

Avoid working with maximum speed at maximum pressure

| t max | 90 °C | |

| p max | Air | 16 bar |

| p max | Water | 30 bar |

| p max | Oil | 100 bar |

| p max | Olio per n<15 RPM | 250 bar |

| n max | 250 RPM |

.jpg)